Finite Element Analysis (FEA) is a powerful engineering and simulation technique that assists in decision-making processes in various industries, particularly in the field of mechanical and structural engineering. FEA helps decision-makers by providing valuable insights into the behavior and performance of structures and systems under different conditions. Here’s how FEA assists in decision making:

Finite Element Analysis (FEA) is a powerful engineering and simulation technique that assists in decision-making processes in various industries, particularly in the field of mechanical and structural engineering. FEA helps decision-makers by providing valuable insights into the behavior and performance of structures and systems under different conditions. Here’s how FEA assists in decision making:

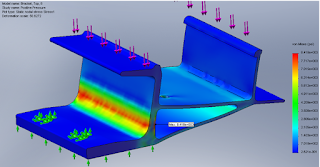

- Performance Assessment: FEA allows engineers and designers to assess the performance of a product or structure before it is built or implemented in the real world. This assessment can include factors like stress, deformation, and temperature distribution. FEA assists decision making allows performance to be improved early in the design process when changes are still relatively inexpensive.

- Safety and Reliability: FEA helps in evaluating the safety and reliability of designs. Engineers can use FEA to predict how a structure or component will behave under extreme conditions, ensuring that it meets safety standards and can withstand anticipated loads and forces. FEA assists decision making by finding reliability and safety concerns early in the design process.

- Optimization: FEA enables the optimization of designs. By running simulations with different parameters and configurations, engineers can identify the most efficient and cost-effective design options. This can lead to resource savings and improved performance.

- Material Selection: FEA aids in selecting the most suitable materials for a given application. It allows engineers to assess how different materials will perform under specific conditions, helping them make informed decisions about material choices.

- Failure Analysis: FEA can predict potential failure modes and points in a design. This information is crucial for identifying weak spots in a structure and making design modifications to prevent catastrophic failures.

- Cost Reduction: By identifying design flaws and weaknesses early in the development process, FEA assists decision making helps reduce the cost of iterations and redesigns. This can save both time and resources.

- Compliance with Regulations: In many industries, FEA is used to ensure that designs comply with industry-specific regulations and standards. This is vital for obtaining certifications and approvals.

- Design Validation: FEA provides quantitative data that can be used to validate design decisions. Engineers can use simulation results to demonstrate that a product or structure will meet its intended purpose and perform within specified parameters.

- Risk Management: FEA helps in risk management by identifying potential risks and weaknesses in designs. Decision-makers can then take proactive measures to mitigate these risks and improve product or system reliability.

- Informed Decision-Making: FEA provides decision-makers with data-driven insights rather than relying solely on intuition or assumptions. This leads to more informed and confident decision-making processes.

- Prototyping Reduction: By using FEA to refine designs before physical prototypes are built, organizations can reduce the need for costly and time-consuming physical testing.

- Continuous Improvement: FEA can be employed in ongoing product development and improvement cycles. It allows for continuous refinement and optimization of products and systems throughout their lifecycle.

In summary, FEA assists decision making by providing a thorough understanding of how structures and systems will behave under various conditions. This enables informed decisions regarding design, materials, safety, cost-effectiveness, and compliance, ultimately leading to better-engineered products and systems. Contact Situs Engineering to learn more about how your design process can benefit from finite element analysis.